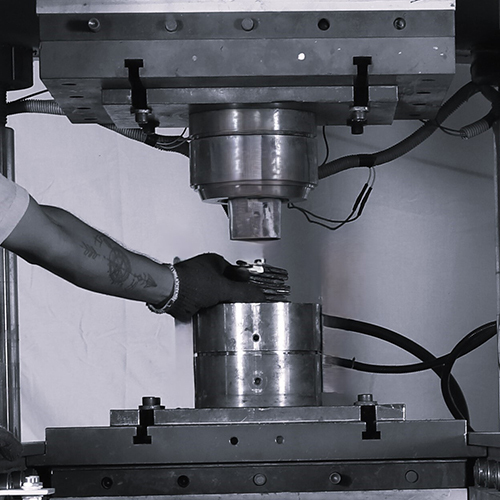

Rubber part prototype moulding – bringing your ideas to life

We specialize in rubber part prototype moulding, providing fast and efficient solutions to bring your designs from concept to reality. Our expertise in moulding high-quality rubber prototypes ensures that your product is ready for full-scale production with precision and confidence.

Rubber part prototype moulding involves the creation of pre-production prototypes of rubber components. This process allows manufacturers to test and validate the design, fit, function, and performance of rubber parts before committing to full-scale production.

Prototype moulding is an essential step in product development because it helps

Validate Design

Ensure the part fits and functions as intended

Test Material Performance

Evaluate how the rubber material reacts to stress, temperature, and environmental conditions.

Identify and Correct Issues

Spot any design or production flaws early, avoiding costly mistakes in mass production.

Assess Aesthetics and Finish

Confirm the part’s appearance, texture, and finish match your expectations.

Advantages of rubber prototype moulding with Anton seals

Fast turnaround

Our streamlined prototyping process allows us to deliver rubber prototypes in a short timeframe, enabling you to move quickly from concept to production.

Cost-effective

Prototyping allows you to test your design without the high costs associated with full-scale production, helping you save time and money by identifying and addressing issues early.

Customization

Whether you need a single prototype or multiple variations, we can tailor the design, material, and moulding process to meet your specific requirements.

Material expertise

We offer a wide range of rubber materials, including silicone, nitrile, EPDM, neoprene, and more, ensuring you have the right material for your product’s unique demands.

Comprehensive testing

Our prototypes undergo rigorous testing to ensure that they meet the highest standards of quality, durability, and performance.