Elastomer product qualification testing – ensuring performance and reliability

We understand that elastomer components must meet stringent performance and safety standards. Our elastomer product qualification testing services ensure that every product is thoroughly tested and validated to withstand real-world applications, providing our clients with the confidence they need in the durability, reliability, and performance of their elastomer products.

Elastomers are used in a wide range of industries, from automotive and aerospace to medical devices and consumer products. These components often face harsh environments, including extreme temperatures, high pressures, chemical exposure, and mechanical stress.

Qualification testing is essential to :

Validate design

Ensure that the elastomer product functions as intended under the expected operating conditions.

Ensure safety and compliance

Meet industry-specific regulations and standards such as ASTM, ISO, FDA, or REACH.

Prevent failures

Identify any potential weaknesses or design flaws before full-scale production.

Improve product lifespan

Ensure that the product can withstand long-term wear and environmental exposure.

Our elastomer qualification testing services

At Anton Seals, we offer a comprehensive range of qualification testing services tailored to your elastomer products’ specific requirements. Our testing services include

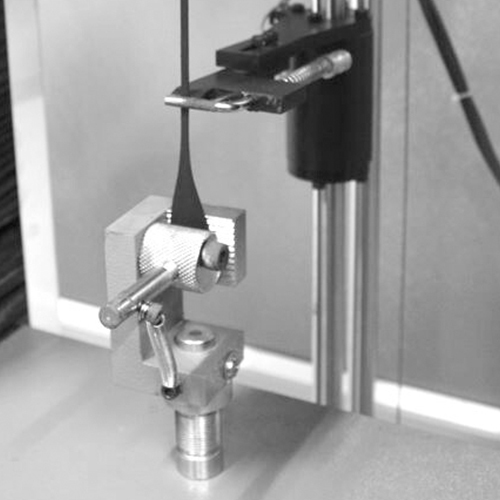

1.Mechanical testing

We evaluate the mechanical properties of elastomers to ensure they meet your specifications for flexibility, durability, and load-bearing performance. Key tests include:

2.Thermal testing

Elastomers are often exposed to a wide range of temperatures in real-world applications. We conduct various thermal tests to assess the performance and stability of elastomers under both high and low temperatures:

3.Chemical resistance testing

Many elastomer products are exposed to chemicals, oils, fuels, and solvents in their operational environment. Our chemical resistance testing evaluates how well the elastomer can withstand these exposures without degrading. Tests include:.

4.Environmental testing

Elastomer products are often subjected to various environmental factors that can affect their performance. We simulate real-world conditions to ensure your product’s longevity, including:

5.Aging and fatigue testing

Long-term durability is crucial for elastomer components. We offer aging and fatigue tests to ensure your product can maintain its performance over time, including:

6.Electrical testing

For elastomers used in electrical insulation or conductive applications, we offer a range of electrical property tests, including:

7.Regulatory and standards compliance

We help ensure that your elastomer products comply with relevant industry standards and regulations, including:

ISO (International Organization for Standardization) for quality and performance.

ASTM (American Society for Testing and Materials) standards for elastomer testing.

FDA regulations for elastomers used in food and medical applications.

REACH and RoHS for environmental and chemical safety standards.

Our commitment to quality and precision

At [Company Name], we are committed to delivering reliable and accurate elastomer qualification testing. Our testing facilities are equipped with the latest technologies, and our experienced team of engineers and material scientists ensures that every test is conducted with the highest standards of precision and repeatability. We work closely with our clients to understand their specific requirements and provide detailed reports with actionable insights for product improvements.

This content provides a detailed overview of elastomer product qualification testing, emphasizing the importance of rigorous testing for performance, durability, and compliance. You can adjust the tone, services, or details based on your company’s specific testing capabilities and target audience.